Bid farewell to the nightmare of grinding wheel dressing! Diamond dressing rollers double your produ

"Even with three grinding machines running non-stop, we still can't keep up with the orders. The master is working overtime every day, but the defective rate is shockingly high! "Using a single-point diamond pen to repair an arc raceway, we spend a long time adjusting the precision, but it's still not right. After repairing, we have to readjust if we don't grind 20 parts! "Replacing the single-point pen costs 6,000 yuan a month, and the downtime for tool changes is longer than the processing time! Are you, as a machinist, tortured by these grinding wheel dressing problems every day? As the core link of precision machining, grinding wheel dressing, once it goes wrong, efficiency, precision, and cost will all be compromised. The three major nightmares of traditional single-point diamond pen dressing - low efficiency, poor precision, and high cost - have long become the 'bottleneck' problems that restrict productivity upgrades.

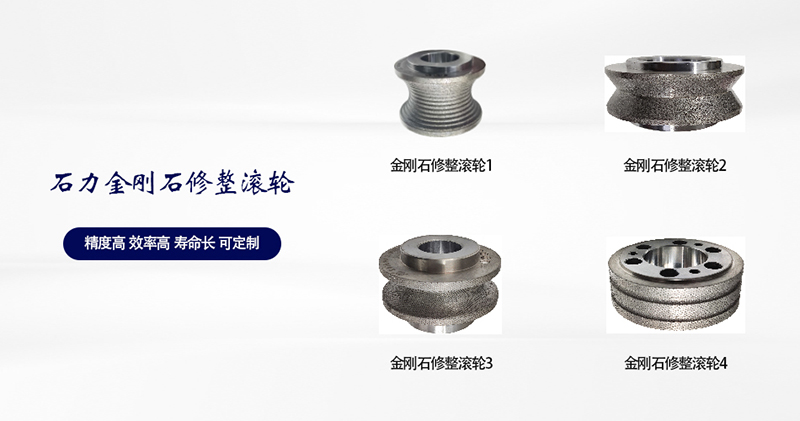

Today, I will introduce to you a cutting-edge technology in the workshop that can solve this dilemma - the high-precision diamond dressing roller! Leveraging its core advantage of surface contact dressing, it addresses the traditional dressing pain points from the root, enabling batch processing to achieve "doubled efficiency, up-to-standard precision, and significantly reduced cost". It has become a standard for capacity upgrades in industries such as bearings, automotive components, aerospace, and more!

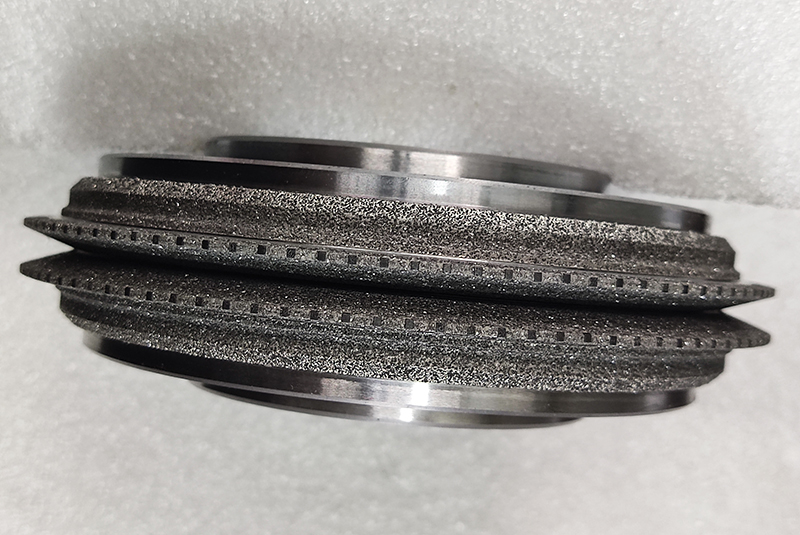

Let's first talk about the efficiency issue you are most concerned about. With traditional single-point diamond pen dressing, it takes 5-8 minutes to dress a common flat grinding wheel. When encountering complex surfaces such as bearing race circular arcs and gear tooth grooves, the technician repeatedly adjusts the angle, tests the cut, and measures, and it is considered lucky if it can be fixed in half an hour, which directly delays the production plan. However, the diamond dressing roller adopts surface contact dressing technology, which compresses the complex grinding wheel dressing time from 30-60 minutes to within 10 seconds! A certain agricultural machinery factory in Jiangsu previously processed gearbox gears, but due to inaccurate tooth groove contours, manual subsequent grinding was required, limiting daily output. After switching to customized diamond dressing rollers, the grinding wheel was dressed in place in one attempt, eliminating the need for secondary grinding after processing. As a result, the factory produced over 50 more gears per day, directly increasing its production capacity by over 30%.

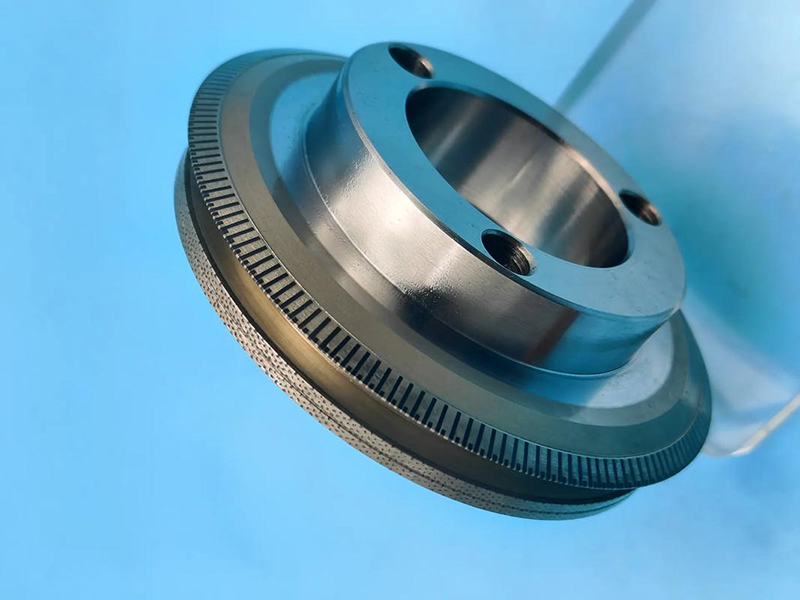

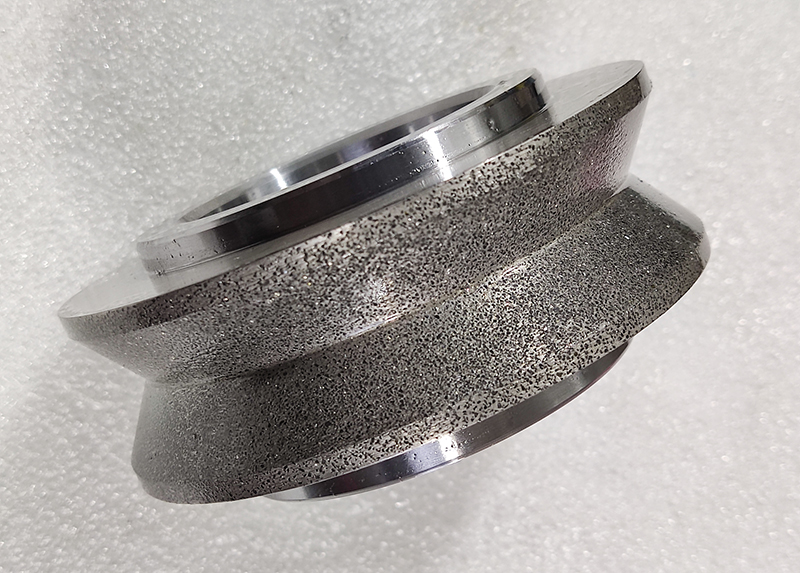

The issues of unstable precision and high defect rates can now be thoroughly resolved. The core of mechanical processing lies in "precision", but the single-point diamond pen relies solely on manual operation by skilled craftsmen. Any slight deviation in force or angle can cause the grinding wheel contour to deform, leading to poor consistency in part precision. A motor factory in Guangdong previously used a single-point pen to repair grinding wheels, resulting in a rotor shaft cylindrical error consistently around 0.005mm, which frequently led to product returns. After switching to a diamond correction roller, the error was directly reduced to 0.002mm. Not only did there no longer be any disputes over product returns, but the factory also secured more orders from high-end customers due to its high precision. This diamond correction roller can control the angular symmetry tolerance to within 0.002mm, with the minimum arc tolerance even as low as 0.001mm, equivalent to 1/50 of the diameter of a human hair. The manufacturing error is less than 1/2 of the workpiece tolerance, allowing it to perfectly replicate its own precise contour onto the grinding wheel and then onto the workpiece surface, ensuring consistent precision in mass-produced parts.

What's even more surprising is that it can help you significantly reduce the overall cost. The single-point diamond pen is a single-point contact grinding wheel, which wears out extremely quickly. It generally needs to be repaired dozens of times before it becomes useless, and the tooling cost can easily reach several thousand yuan a month. However, the diamond correction roller has superb wear resistance, and can complete 15,000 to 20,000 repairs with just one roller, which is 20-30 times longer than an ordinary diamond pen. A machine tool factory in Shandong calculated the cost: when using the single-point pen, the monthly tooling cost is 6,000 yuan. After switching to the diamond correction roller, one roller can last for more than half a year, with an average monthly cost of only 1,800 yuan. This saves more than 50,000 yuan in tooling costs annually, enough to buy accessories for two new grinding machines. At the same time, it does not require frequent replacement, significantly reducing the downtime of the grinding machine, avoiding loss of production capacity, and indirectly creating more revenue.

Facing complex surface machining challenges, it can handle them with ease. For complex contours that cannot be repaired by a single-point pen, such as the curved surface of turbine blades, the tooth groove of gearbox gears, and the special sealing surface of hydraulic valves, the diamond dressing roller can customize a unique contour according to the needs of the part. After installation, it can achieve perfect dressing in one go, reducing the switching loss of multi-machine step-by-step processing and avoiding the accumulation of errors between processes. After adoption by a certain aeroengine blade manufacturer, the processing cycle of turbine blade tenon teeth was shortened from 14 days to 3 days, with a 367% increase in production capacity; after adoption by a certain automotive steering system supplier, the grinding yield of aluminum alloy increased from 91% to 99.3%, and the annual scrap loss decreased by millions of yuan.

More suitable for modern production, it can also lower the technical threshold and facilitate automation upgrades. Traditional dressing requires extremely high technical skills from the master, and the cost and time to train a skilled worker are high and long; whereas the diamond dressing roller system comes with preset standardized operating parameters, which can be mastered by ordinary workers after just 2 hours of training, reducing labor costs by 70%. At the same time, it can integrate the intelligent compensation function of a laser displacement sensor, which can monitor the wear of the grinding wheel in real time and automatically adjust the dressing amount, keeping the error within ±0.5μm. It perfectly fits the automated production line that operates continuously for 24 hours, easily achieving unmanned operation.

Whether you specialize in bearings, automotive components, or precision machining for aerospace applications, and regardless of whether you are facing challenges such as low efficiency, poor precision, high costs, or difficulties in processing complex surfaces, this diamond dressing roller can precisely meet your needs. We offer customized development services, and can adjust the installation dimensions according to the connection dimensions of your machine tool dressing device, ensuring seamless integration with your existing production line.

Don't let traditional dressing methods slow down your production capacity and erode your profits anymore! Click the link below now to obtain a customized solution, receive a free industry-compatible selection guide, and unlock a new processing experience of "doubled efficiency, stable precision, and significantly reduced costs"! Let the diamond dressing roller become your productivity upgrade tool and easily lead the way in precision machining!

Henan Shili Diamond Products Co., Ltd., established in 2003 with a registered capital of 12 million yuan and assets of 40 million yuan, is a high-tech enterprise integrating research and development, production, and sales of diamond products.

The company is located in the Intelligent Equipment Manufacturing Industrial Park at the southern section of Hengshan Road, National Economic and Technological Development Zone, Luohe City. It specializes in the processing and sales of diamond and other superhard materials, hardware rollers, abrasives, and jewelry inlaying. The main products include four series: diamond dressing tools, diamond grinding tools, diamond measuring tools, and diamond cutting tools. The company has successively become a high-quality supplier to internationally renowned enterprises such as Liaoning Wuyi Ba Internal Combustion Engine Parts Co., Ltd., Harbin Electric Machinery Factory, Chongqing Sanai Hailing, Hangzhou Machine Tool Factory, and Dongfeng Motor. Its products are sold well both domestically and internationally.

As the Diamond Precision Dressing Tool Engineering Research Center in Henan Province, our company currently boasts one engineering technology research center and a technical R&D team that represents the domestic industry standard. We have developed over 30 new products and obtained 19 utility model patents. Recognized as a "high-tech enterprise," we have also garnered numerous honors.

If you have any further questions or requirements regarding diamond dressing rollers, please feel free to contact us.