1、 Introduction to Diamond Rollers

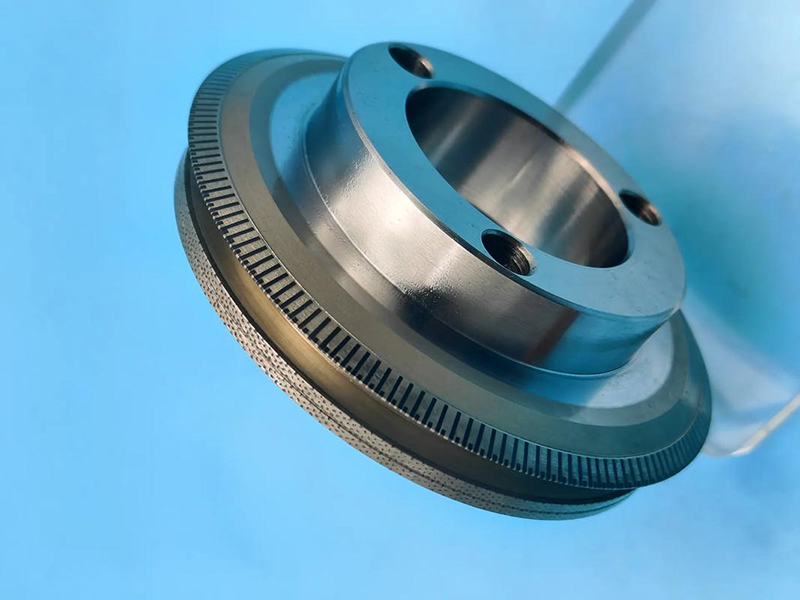

In the grinding process, the appearance of diamond rollers is like a clear stream, bringing new possibilities for improving grinding efficiency and quality. Its unique material and structural design enable it to handle high-intensity grinding tasks with ease, making it an ideal choice for many industrial fields.

Diamond rollers, as specialized machine tools for mass forming grinding and grinding wheel dressing tools for gear grinding machines, stand out for their high efficiency, long service life, and low cost. Compared with the expensive diamond repair pen, its cost-effectiveness advantage is more obvious. During use, the adjustment of the roller requires the use of electric spark technology, so when recommending, it is necessary to fully understand the equipment used by the customer. The design and manufacturing of diamond rollers strictly follow the technical requirements of the processed parts, and their contour shape, size, and accuracy must match the connection size of the trimming device on the user's machine tool.

The superiority of diamond rollers is mainly reflected in their good adaptability in different equipment, which needs to be used according to specific machine characteristics.

2、 Application Fields

Diamond rollers are widely used for grinding wheel dressing of workpieces such as gears, bearings, crankshafts, lead screws, ball cages, blades, oil nozzles, and oil pumps. They can also be used for precision dressing of cutting tools, guide rails, micro rails, calipers, etc.

3、 Working principle and advantages and disadvantages

1. Working principle

Diamond rollers play a role in the dressing device of grinding machines, specifically used for dressing ordinary ceramic grinding wheels or CBN grinding wheels. After the shaping grinding of the grinding wheel, the processing of the parts is completed, so that the precise contour, size, and accuracy of the diamond roller can be fully replicated on the surface of the processed parts.

2. Characteristics and advantages

The use of diamond rollers for grinding processing makes the machine operation simple and easy to understand, with relatively low technical requirements for the operators. This process ensures that the processed products have highly consistent accuracy and quality, significantly improving production efficiency while reducing manufacturing costs. In addition, diamond rollers are also easy to automate grinding processes, further optimizing the production process.

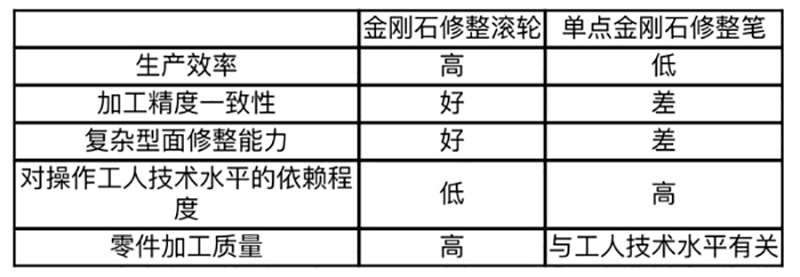

3. Comparison with traditional methods

Compared with traditional single point diamond pen trimming, using diamond rollers for grinding processing has significantly improved production efficiency. At the same time, this process can ensure higher surface quality and precision of the processed parts, which is very suitable for the needs of high-precision and large-scale production.

4、 Precautions for use

When selecting diamond, its particle size should be slightly coarser than that of the dressing wheel, and ensure that the diamond particle size is uniform and approximately spherical. The commonly used particle size range is 36 #~100 #.

It is recommended that the direction of the linear velocity at the contact point between the roller and the grinding wheel be the same, and the ratio of the linear velocity of the roller to the linear velocity of the grinding wheel (qd value) should be controlled within the range of+0.3~+0.7, and should not exceed+1. When repairing, the cutting amount of the roller should be set to 0.5~1 μ m per rotation of the grinding wheel, and the total amount of grinding wheel repaired each time should be about 0.02~0.04mm, and the polishing time should be shortened as much as possible.

The manufacturing error of diamond rollers should be about half of the workpiece tolerance, and the fit clearance between the roller hole and the installed bearing should be 2-4 μ m.

Natural or synthetic diamonds can be used. If synthetic diamonds are chosen, high-strength grades of diamonds should be selected, such as SCD or high-strength SMD diamonds specifically designed for grinding steel.

When manufacturing rollers, general precision rollers can be manufactured using external plating or sintering methods, while high-precision and complex profile rollers are recommended to be manufactured using internal plating methods, supplemented by grinding and finishing.

When using diamond rollers to repair grinding wheels, it is necessary to follow the operation process of fast forward (avoid touching the grinding wheel) → slow forward (feed in at the required cutting speed) → light repair → exit to ensure error free operation and ensure the service life of the rollers.

Henan Shili Diamond Products Co., Ltd. was established in 2003 with a registered capital of 12 million yuan and assets of 40 million yuan. It is a national high-tech enterprise that integrates research and development, production, and sales of diamond products.

The company is located in the Intelligent Equipment Manufacturing Industrial Park, Hengshan Road South Section, National Economic and Technological Development Zone, Luohe City. Its main products include diamond and other superhard materials, hardware rollers, abrasives and grinding tools, jewelry inlay processing, and sales. The main products include four series: diamond dressing tools, diamond grinding tools, diamond measuring tools, and diamond cutting tools. We have successively become a high-quality supplier to internationally renowned enterprises such as Liaoning 518 Internal Combustion Engine Parts Co., Ltd., Harbin Electric Machinery Factory, Chongqing Sanai Hailing, Hangzhou Machine Tool Factory, Dongfeng Motor, etc. Our products are sold well both domestically and internationally.

As the Engineering Research Center for Diamond Precision Trimming Tools in Henan Province, the company currently has one engineering technology research center and one technical research and development team representing the domestic industry level. It has developed more than 30 new products, obtained 19 utility model patent authorizations, been recognized as a "national high-tech enterprise", and has received numerous honors.

If you have any further questions or needs about diamond rollers, please feel free to contact us at any time.