Guidelines and safety precautions for using diamond grinding wheels

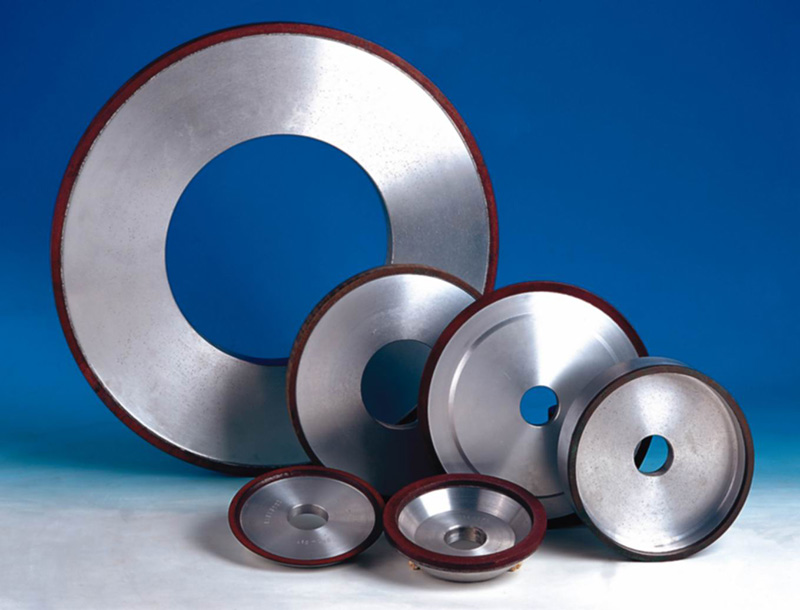

Alloy diamond grinding wheel is a circular solid grinding tool made mainly from diamond abrasive, bonded with metal powder, resin powder, ceramic or electroplated metal binders. Diamond grinding wheels have significant characteristics such as high hardness and wear resistance, high precision and efficiency, and good thermal conductivity, and are widely used in fields such as hard and brittle material processing, industrial manufacturing, and special material processing.

Diamond grinding wheels are renowned for their ultimate hardness and excellent grinding ability, and are known as the "indestructible" grinding tool. However, in order to fully utilize its performance and extend its service life, a series of precautions need to be followed during use.

Precautions for using diamond grinding wheels

1. Scope of application of diamond grinding wheel

Diamond grinding wheels, as a precious tool, are designed specifically for processing high hardness materials and are not suitable for grinding ordinary steel or other soft materials.

2. Installation and preparation for use

The diamond grinding wheel installed with a flange must undergo a static balance test before it can be put into use. Be sure to note that the grinding wheel must not be disassembled from the flange plate before it is used up.

3. Machine tool requirements and accuracy

Machine tools using diamond grinding wheels must have sufficient rigidity, strict precision requirements for the spindle (with radial runout controlled within 0.01 millimeters), and the ability to provide micro horizontal feed.

4. Grinding dosage and coolant selection

The selection of grinding quantity is crucial. The following data can be used as a reference:

The recommended linear speed of the grinding wheel is as follows:

Metal bond grinding wheel, with a dry grinding time of 10-15 seconds and a wet grinding time of 20-35 seconds;

Resin bonded grinding wheel, set at 15-30/s for dry grinding and 25-40/s for wet grinding.

The workpiece line speed is usually controlled within the range of 10-15 */min.

The grinding depth should be carefully set, as excessive depth can cause rapid wear of the grinding wheel and is not conducive to grinding efficiency. It is generally recommended to control the grinding depth within 0.005-0.01 millimeters per oxygen stroke. At the same time, the grinding depth should be smaller for fine abrasive particles, especially in the absence of coolant.

The longitudinal feed rate is generally set to 10-15 meters per minute.

When grinding, coolant should be used as much as possible. This not only improves the efficiency and quality of grinding, but also effectively reduces the wear of the grinding wheel. Common coolant includes kerosene, light diesel oil and light engine oil, among which kerosene is usually the best choice.

5. Repair of new grinding wheel

When using a new diamond grinding wheel for the first time, it is necessary to make appropriate adjustments to ensure its precise shape (such as outer roundness and end face flatness). This step can be completed by using a silicon carbide grinding wheel or manually grinding a flat metal or glass plate with silicon carbide abrasive, especially for the finishing of the grinding wheel end face. At the same time, in order to save costs, natural finishing methods can be used: first, use a new grinding wheel for rough grinding, wait for it to wear to the appropriate shape, and then switch to fine grinding. During the grinding process, if it is found that the grinding wheel has become insufficiently sharp or blocked, you can hold a silicon carbide grinding wheel and gently adjust the working surface of the grinding wheel.

6. Operating safety regulations

In daily operation, the operator must stand on the side of the grinding wheel and must not operate on the front of the grinding wheel. This is to prevent the grinding wheel from flying out or breaking in case of malfunction, thereby avoiding harm to the operator.

Some operators habitually use the side of the grinding wheel for grinding, regardless of the type of grinding machine or the type of grinding wheel. This practice seriously violates safety operating procedures and is a typical violation of regulations. According to regulations, grinding wheels with a circumferential surface as the working surface are not allowed to use side grinding. This type of grinding wheel has higher strength in the radial direction, but relatively weaker in the axial direction. If the operator applies excessive force on this type of grinding wheel, it may cause the wheel to break and even result in personal injury. Therefore, in practical operation, such behavior should be resolutely eliminated.

In daily operations, it is also common for two operators to use a grinding machine together to meet production schedules or save time. This behavior seriously violates safety operating procedures, so it must be resolutely eliminated. When the number of grinding machines is insufficient, measures should be taken to increase the number of grinding machines, rather than allowing two operators to share one grinding machine at the same time.

When using a grinding machine, some operators, especially young operators, often exert excessive force in pursuit of grinding speed. However, this excessive operation method not only poses a threat to the safety of the grinding machine, but may also cause the grinding wheel to break or even fly out and injure people. Therefore, such behavior must be strictly prohibited to ensure operational safety.

Henan Shili Diamond Products Co., Ltd. was established in 2003 with a registered capital of 12 million yuan and assets of 40 million yuan. It is a national high-tech enterprise that integrates research and development, production, and sales of diamond products.

The company is located in the Intelligent Equipment Manufacturing Industrial Park, Hengshan Road South Section, National Economic and Technological Development Zone, Luohe City. Its main products include diamond and other superhard materials, hardware rollers, abrasives and grinding tools, jewelry inlay processing, and sales. The main products include four series: diamond dressing tools, diamond grinding tools, diamond measuring tools, and diamond cutting tools. We have successively become a high-quality supplier to internationally renowned enterprises such as Liaoning 518 Internal Combustion Engine Parts Co., Ltd., Harbin Electric Machinery Factory, Chongqing Sanai Hailing, Hangzhou Machine Tool Factory, Dongfeng Motor, etc. Our products are sold well both domestically and internationally.

As the Engineering Research Center for Diamond Precision Trimming Tools in Henan Province, the company currently has one engineering technology research center and one technical research and development team representing the domestic industry level. It has developed more than 30 new products, obtained 19 utility model patent authorizations, been recognized as a "national high-tech enterprise", and has received numerous honors.

If you have any further questions or needs about diamond grinding wheels, please feel free to contact us at any time.