A Comprehensive Guide to Diamond Dressing Wheels: Sintering, Electroplating, and CVD?

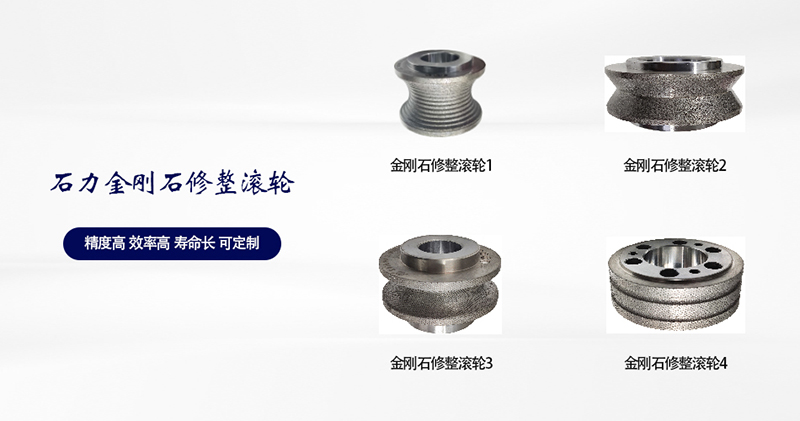

In the field of precision machining, the dressing of CBN grinding wheels is a critical step that directly impacts the machining quality and efficiency of workpieces. As Henan's Diamond Precision Dressing Tool Engineering Research Center and a high-tech manufacturing facility with over 30 years of expertise, Shili offers efficient cutting and grinding tools along with comprehensive solutions, including diamond rolls—a high-performance wheel dressing tool.

1. Working Principle of Diamond Grinding Wheel

The working principle of a diamond dresser involves installing it on the dressing device of a grinding machine to dress conventional ceramic or CBN grinding wheels. After the grinding wheel is formed, the workpiece is ground, transferring the contour, precision, and dimensions of the diamond dresser to the surface of the machined part. This method is characterized by simple operation, low technical requirements for operators, ensuring consistent product accuracy and stable quality. It significantly improves production efficiency and product quality, reduces manufacturing costs, and facilitates the automation of grinding processes.

2. Advantages of Diamond Grinding Wheels

Compared to traditional single-point diamond pen dressing, diamond rolls offer significant advantages:

Efficiency Improvement: The working part of the diamond grinding wheel is upgraded from point to surface, significantly enhancing machining efficiency.

Precision Consistency: Reduces reliance on worker skills and proficiency, enhancing the machining quality and uniformity of part precision.

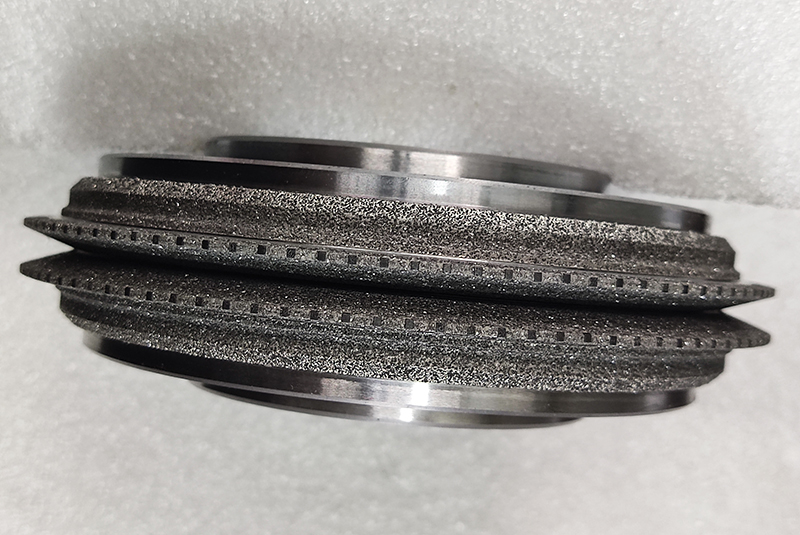

Complex Shape Dressing: Suitable for dressing wheels with intricate shapes, while single-point diamond dressing tools are primarily used for wheels with simpler workpiece shapes.

Cost-effectiveness: Diamond grinding wheels are used for plunge dressing, which can effectively reduce machining costs and result in lower overall costs compared to CNC dressing.

Manufacturing Methods of Diamond Grinding Wheels

The manufacturing methods of diamond grinding wheels are diverse, including:

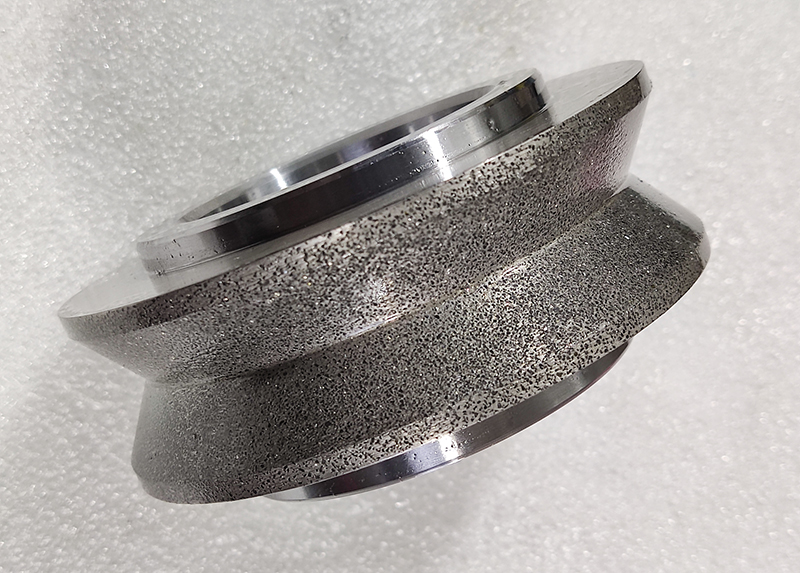

Hand-planted sintering method: highly durable, divided into hand-planted sintering rollers and randomly distributed sintering rollers.

Electroplating method: Capable of producing small and complex-shaped rollers, including internal plating and external plating.

CVD Diamond Grinding Wheel: A novel material with excellent dressing performance for CBN grinding wheels.

3. Precautions for Using Diamond Rolls

When using a diamond wheel, the following points should be noted:

Diamond grain size selection: The grain size should be one grade coarser than that of the grinding wheel being dressed. Choose diamond particles with nearly uniform size and approximately spherical shape.

Adjustment speed control: The linear velocity direction at the contact point between the roller and the grinding wheel should be aligned. The ratio of the roller's linear velocity to the grinding wheel's linear velocity (qd value) is preferably set between +0.3 and +0.7.

Grinding wheel dressing control: The total amount of dressing per operation should be 0.02~0.04 mm, and the dressing time should be minimized.

Wheel accuracy: The manufacturing error of the diamond grinding wheel should be approximately less than half of the workpiece tolerance.

4. Industries Suitable for Diamond Grinding Wheels

Diamond grinding wheels are widely used in various industries such as bearings, automotive components, textile machinery, and aerospace, where high-precision wheel dressing tools are required to ensure product quality.

By utilizing Henan Shili's diamond rollers, customers can achieve more efficient and precise CBN wheel dressing, thereby enhancing overall machining efficiency and product quality.

Henan Shili Diamond Products Co., Ltd., established in 2003 with a registered capital of 12 million yuan and assets of 40 million yuan, is a national high-tech enterprise specializing in the research, production, and sales of diamond products.

The company is located in the Intelligent Equipment Manufacturing Industrial Park on the south section of Hengshan Road in the National Economic and Technological Development Zone of Luohe City. It specializes in the production and sales of diamond and other superhard materials, metal rollers, abrasives and grinding tools, jewelry inlay processing, and offers four main product series: diamond dressing tools, diamond grinding tools, diamond measuring tools, and diamond cutting tools. It has become a preferred supplier for internationally renowned enterprises such as Liaoning Wuyi8 Internal Combustion Engine Parts Co., Ltd., Harbin Electric Machinery Factory, Chongqing Sanai Hailing, Hangzhou Machine Tool Factory, and Dongfeng Motor Corporation, with its products widely sold both domestically and internationally.

As the Henan Diamond Precision Dressing Tool Engineering Research Center, the company currently operates one engineering technology research center, maintains a technical R&D team that represents the domestic industry standard, has developed over 30 new products, secured 19 utility model patents, and is recognized as a "National High-Tech Enterprise." It has also received numerous honors.

If you have any further questions or requirements regarding diamond grinding wheels, please feel free to contact us.