How to choose between diamond dressing rollers and diamond finishing brushes?

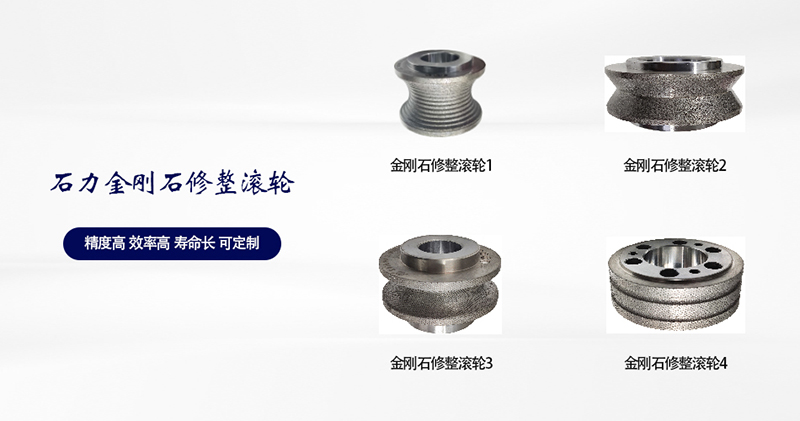

During the grinding process of the grinding wheel, the wheel will experience wear and deformation. In order to ensure the sharpness or accuracy of the wheel, we need to trim it. Today we will learn about a diamond tool used for grinding wheel dressing, the diamond dressing roller.

We all know that the dressing of grinding wheels can be done with dressing oilstones, diamond finishing brushes, and diamond dressing rollers. What is the difference between using diamond dressing rollers to repair grinding wheels and other dressing methods?

The first step in using ordinary oil stone or grinding wheel dressing is to remove dull abrasives or blocked surfaces on the surface of the grinding wheel, and restore the sharpness of the grinding wheel. As they belong to ordinary grinding tools, they are mainly used for sharpening.

Diamond pens and diamond rollers, due to the high hardness of the abrasive, can be used to shape grinding wheels. The types of diamond pens include sintered, single point, and multi-point diamond pens. By precisely adjusting the shape and angle of the grinding wheel, the smoothness and accuracy of the machined surface are ensured, and the machining accuracy and efficiency are improved. They are suitable for various high-precision grinding occasions.

The main differences between sintered diamond rollers and electroplated diamond rollers lie in their manufacturing process, durability, and accuracy.

Manufacturing process: Sintered diamond rollers are made by manually implanting or randomly distributing large diamond particles on the surface of the substrate, and then subjecting them to high-temperature sintering. Electroplated diamond rollers uniformly deposit diamond onto the surface of the substrate through electroplating.

Durability: Sintered diamond rollers have strong durability. Due to the diamond particles being embedded on the surface of the substrate and fixed by high-temperature sintering, they have strong wear resistance.

Accuracy: The accuracy of electroplated diamond rollers is higher than that of sintered diamond rollers. Electroplated diamond rollers ensure their accuracy through precise control of electroplating processes and metal cutting, enabling small and complex shape adjustments.

What are the differences between diamond rollers and diamond finishing tools, both of which belong to diamond finishing tools?

Today we will compare the single point diamond finishing pen with the diamond finishing roller.

1. Structural comparison:

Single point diamond pen: It is a trimming tool composed of a single diamond and a handle. The handle is used for installing and connecting diamonds, while diamonds are used for dressing grinding wheels.

Diamond roller: It is mainly composed of a substrate and diamond particles embedded on the substrate. The substrate is usually made of metal or non-metal materials to withstand friction up to millions of times per second. Diamond particles are irregularly distributed in triangular or quadrilateral shapes and embedded in the matrix.

2. Comparison of usage methods:

Single point diamond pen: When in use, it is necessary to adjust its position on the machine tool to ensure that it can fully contact the grinding wheel. Then, through the movement of the machine tool, the diamond pen is driven to trim the grinding wheel.

Diamond roller: During use, the diamond roller comes into contact with the grinding wheel, and through the rotation of the roller, diamond particles can adjust the grinding wheel.

3. Analysis of advantages and disadvantages:

Single point diamond pen: Its main advantage is that it is suitable for various types of grinding wheels and can be effectively trimmed. However, due to the structural limitations of single point diamond pens, their trimming efficiency is relatively low.

Diamond roller: Due to its special structure, diamond rollers have high dressing efficiency and can quickly and effectively dress grinding wheels. In addition, the design of the diamond roller allows it to complete a large amount of trimming work in a short period of time, reducing trimming costs. However, diamond rollers have relatively low technical requirements for machine tools, which may result in lower machine tool costs and expenses.

If repairing ordinary frosted wheels such as corundum and silicon carbide grinding wheels, diamond pens or diamond rollers can be used. If repairing superhard grinding wheels such as diamond and CBN grinding wheels, diamond rollers are the best choice because they are more wear-resistant.

In summary, diamond dressing rollers have the advantages of high efficiency and fast dressing in grinding wheel dressing, especially for dressing superhard grinding wheels. At the same time, the design of diamond rollers also reduces the cost of dressing and improves the accuracy and stability of the grinding wheel. When choosing a dressing tool, it is necessary to choose according to the type of grinding wheel and dressing requirements. Single point diamond pens are suitable for dressing various types of grinding wheels, while diamond rollers can be used to dress both regular grinding wheels and superhard grinding wheels. For high-efficiency batch dressing, diamond rollers are the most suitable choice.

Henan Shili Diamond Products Co., Ltd. was established in 2003 with a registered capital of 12 million yuan and assets of 40 million yuan. It is a national high-tech enterprise that integrates research and development, production, and sales of diamond products.

The company is located in the Intelligent Equipment Manufacturing Industrial Park, Hengshan Road South Section, National Economic and Technological Development Zone, Luohe City. Its main products include diamond and other superhard materials, hardware rollers, abrasives and grinding tools, jewelry inlay processing, and sales. The main products include four series: diamond dressing tools, diamond grinding tools, diamond measuring tools, and diamond cutting tools. We have successively become a high-quality supplier to internationally renowned enterprises such as Liaoning 518 Internal Combustion Engine Parts Co., Ltd., Harbin Electric Machinery Factory, Chongqing Sanai Hailing, Hangzhou Machine Tool Factory, Dongfeng Motor, etc. Our products are sold well both domestically and internationally.

As the Engineering Research Center for Diamond Precision Trimming Tools in Henan Province, the company currently has one engineering technology research center and one technical research and development team representing the domestic industry level. It has developed more than 30 new products, obtained 19 utility model patent authorizations, been recognized as a "national high-tech enterprise", and has received numerous honors.

If you have any further questions or needs about diamond rollers, diamond pens, or diamond grinding wheels, please feel free to contact us at any time.