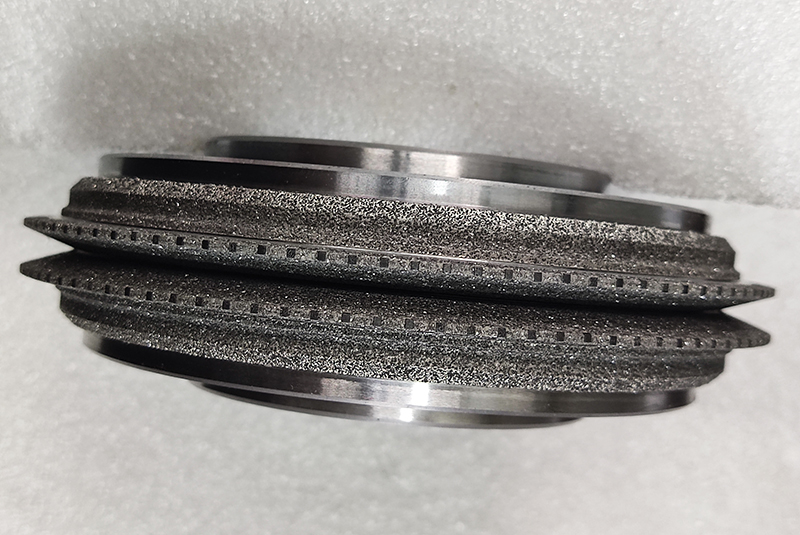

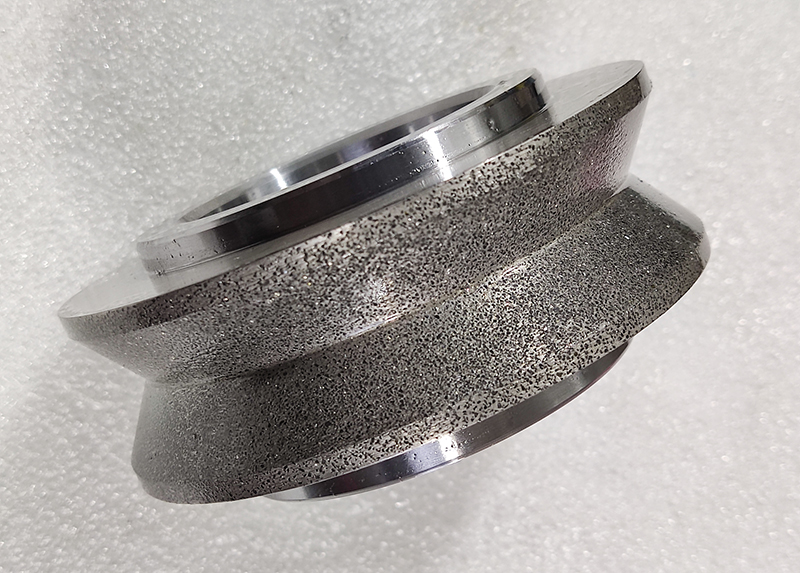

Precision Processing Tool! Diamond Dressing Wheel Doubles Your Machining Efficiency!

In the daily production of machining in factories, are you often troubled by these issues? Unstable machining precision leads to dimensional deviations exceeding standards in batches of workpieces, causing a sharp drop in product qualification rates and persistently high rework costs; inefficient grinding wheel dressing, where traditional dressing tools not only consume significant time but also require frequent replacements, severely slowing down production progress; over prolonged use, the wear costs of dressing tools continue to rise, greatly compressing a company's profit margins... If you are facing these challenges, consider learning about the "game-changer" that can completely transform the current situation—the diamond dressing wheel.

For machining, precision is the core of product quality. Many factories, even with properly adjusted equipment in the early stages of production, face issues as grinding wheels wear down and become dull over continuous use, ultimately affecting the machining accuracy of workpieces. Traditional dressing methods, such as diamond pen dressing, rely entirely on manual operation, with dressing precision heavily influenced by the operator's technical skill, experience, and responsibility. Any slight oversight can lead to uneven wheel dressing, resulting in roundness errors, excessive surface roughness, and other issues in the final workpieces. In contrast, diamond dressing rolls feature an integral structure combined with high-precision manufacturing processes, ensuring stable contact with the grinding wheel during dressing. This maintains geometric accuracy within a micron-level tolerance. Whether machining precision bearings, gears, or complex mold components, the system guarantees consistent accuracy for every workpiece, raising the product pass rate from 80% to over 99%. This eliminates the hassle of rework caused by precision issues entirely.

Inefficiency is another major "bottleneck" hindering the capacity expansion of factories. Traditional dressing tools require a considerable amount of time for each wheel dressing operation, and the lifespan of the grinding wheel is limited after each dressing, necessitating frequent shutdowns for maintenance. Take a car parts manufacturing plant as an example: previously, diamond pen dressing took 15 minutes per operation, and the dressed grinding wheel could only process 50 workpieces. This alone consumed over 2 hours daily, severely disrupting production flow. After switching to diamond dressing rollers, the single dressing time was reduced to just 3 minutes, with the dressed wheel capable of processing 300 workpieces. The effective machining time increased by nearly 3 hours daily, directly boosting production capacity by 40%. Moreover, diamond dressing rollers exhibit exceptional automation adaptability, seamlessly integrating with CNC grinders to enable unmanned dressing operations, significantly reducing manual intervention and further enhancing productivity.

In terms of cost control, diamond dressing wheels also demonstrate significant advantages. Traditional dressing tools, such as diamond pens, have a relatively short service life and typically require replacement after processing several hundred workpieces, resulting in procurement costs of tens of thousands of yuan annually for dressing tools alone. In contrast, diamond dressing wheels, with their ultra-high hardness and wear resistance, boast a service life 20-30 times that of traditional diamond pens. A high-quality diamond dressing wheel can be used continuously for 1-2 years, significantly reducing the frequency of dressing tool replacements and procurement costs. Moreover, due to the high precision and fast efficiency of diamond dressing wheels, they effectively reduce the rework rate and scrap rate of workpieces, minimizing material waste. Additionally, automated dressing operations help lower labor costs, saving production expenses from multiple dimensions and enhancing the economic benefits of enterprises.

Whether it's solving precision machining challenges, improving production efficiency, or reducing production costs, diamond dressing wheels can provide comprehensive solutions for factory machining users. If you're struggling with various pain points in mechanical processing and eager to enhance productivity, consider choosing diamond dressing wheels—they can become your "diligent assistant" on the production line, helping your company stand out in the fierce market competition!

Henan Shili Diamond Products Co., Ltd., established in 2003 with a registered capital of 12 million yuan and assets of 40 million yuan, is a high-tech enterprise specializing in the research, development, production, and sales of diamond products.

The company is located in the Intelligent Equipment Manufacturing Industrial Park on the southern section of Hengshan Road in the National Economic and Technological Development Zone of Luohe City. It primarily engages in the production and sales of diamond and other superhard materials, metal rollers, abrasives and grinding tools, as well as jewelry setting processing. Its main product lines include diamond dressing tools, diamond grinding tools, diamond measuring tools, and diamond cutting tools. The company has become a preferred supplier for internationally renowned enterprises such as Liaoning Wuyi Eight Internal Combustion Engine Parts Co., Ltd., Harbin Electric Machinery Factory, Chongqing Sanai Hailin, Hangzhou Machine Tool Factory, and Dongfeng Motor Corporation, with its products widely sold both domestically and internationally.

As the Henan Diamond Precision Dressing Tools Engineering Research Center, the company currently operates one engineering technology research center, houses a technical R&D team that represents the domestic industry's standards, has developed over 30 new products, secured 19 utility model patent authorizations, and is recognized as a "High-Tech Enterprise," among other accolades.

If you have any further questions or requirements regarding diamond grinding wheels, please feel free to contact us.