Unveiling the Diamond Grinding Wheel: The "Super Weapon" of the Grinding World

An Introduction to Diamond Grinding Wheels

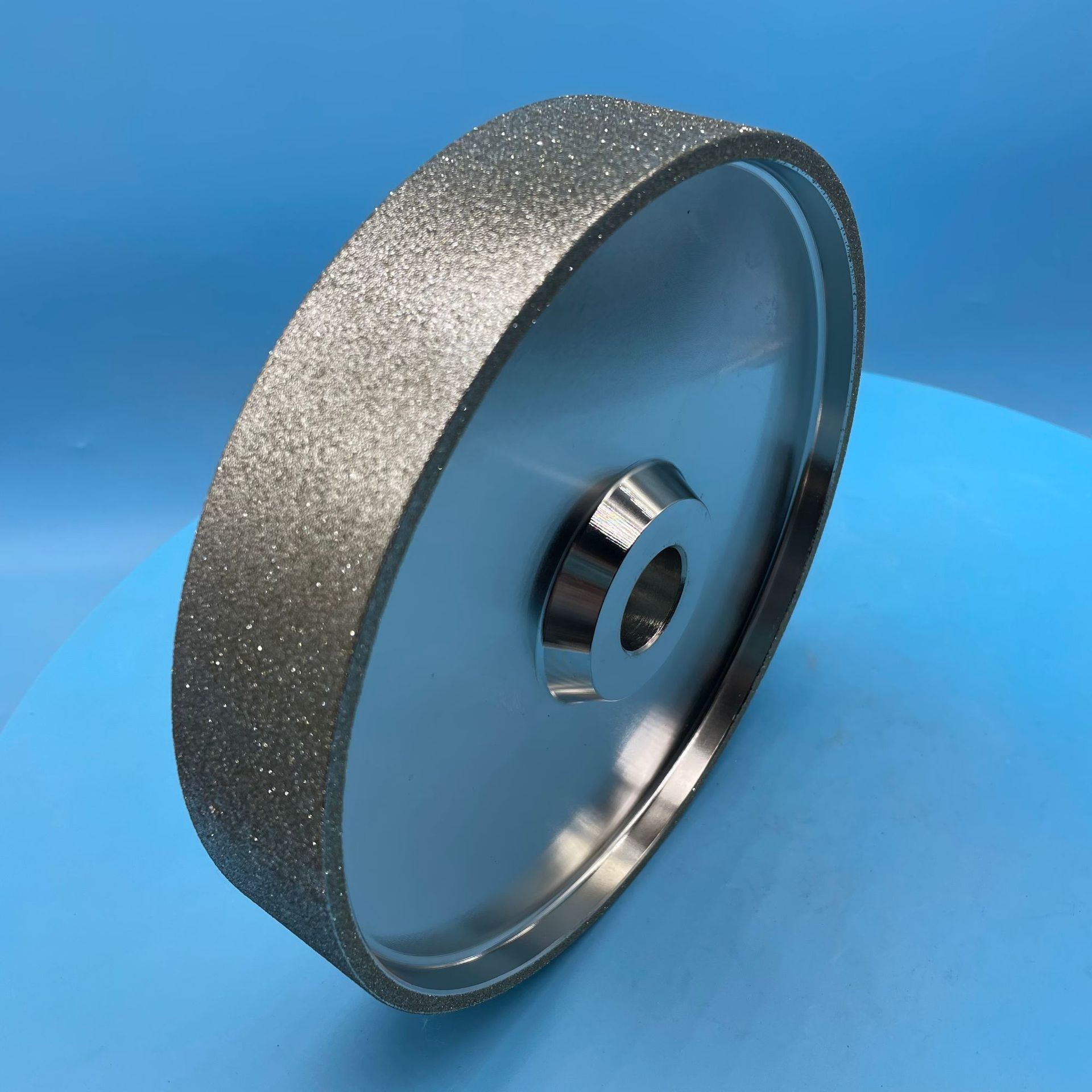

In the vast system of industrial manufacturing, there is a tool that may appear ordinary but plays a pivotal role—diamond grinding wheels. Simply put, diamond grinding wheels are circular fixed abrasive tools with a central through-hole, made from diamond abrasive grains as the raw material, combined with metal powder, resin powder, ceramics, or electroplated metal as binders. Despite their plain and unadorned exterior, their internal structure is highly sophisticated. Typically composed of a diamond abrasive layer, a transition layer, and a substrate, each layer performs its own function while working together to enable diamond grinding wheels to efficiently accomplish various grinding tasks.

Structural and Functional Unveiled

Unique structural composition

The structure of a diamond grinding wheel resembles a highly coordinated team, with each component clearly defined in its role and working in harmony. The outermost abrasive layer serves as the "frontline force" in this grinding operation, composed of diamond abrasives, binders, and fillers. Among these, the diamond abrasives act as the core combat force, leveraging their exceptional hardness to effortlessly "attack" various hard and brittle materials, achieving efficient grinding. The binder functions like a "glue," tightly uniting the diamond abrasives to ensure they do not "fight separately" during operation, while also imparting a certain strength and shape stability to the abrasive layer. The addition of fillers aims to enhance the performance of the abrasive layer, such as improving wear resistance and reducing grinding force.

The transition layer is located between the abrasive layer and the substrate, serving as a "bridge" connecting the two. It primarily consists of binders, metal powder, and fillers. Although it does not directly participate in the grinding process, its role is far from negligible. The transition layer enhances the bonding force between the abrasive layer and the substrate, preventing the abrasive layer from detaching from the substrate under high-speed rotation and intense grinding forces. It acts like an "insurance policy" for the abrasive layer, ensuring the stability and reliability of the entire grinding wheel during operation.

The matrix serves as the "foundation" of the entire grinding wheel, typically fabricated from materials such as aluminum, steel, or bakelite. It supports the abrasive layer and is securely fastened to the grinding machine spindle via a flange during operation, providing stable support for the abrasive layer. In essence, the matrix functions like the foundation of a skyscraper—the more robust the foundation, the taller and sturdier the structure can be. A high-quality matrix ensures the dynamic balance of the grinding wheel during high-speed rotation, reducing vibration and noise, thereby enhancing grinding precision and machining quality.

Excellence showcases strength

The reason why diamond grinding wheels stand out among their counterparts lies in their exceptional set of superior characteristics.

First is the high hardness. As the hardest substance in nature, diamond endows the grinding wheel with unparalleled grinding capabilities. Whether it's hard alloys, ceramics, or difficult-to-machine materials like optical glass, they can all be easily "tamed" by diamond grinding wheels. Compared to ordinary grinding wheels, diamond grinding wheels can complete grinding tasks with higher efficiency, significantly reducing processing time and improving production efficiency.

High wear resistance is another standout feature of diamond grinding wheels. During the grinding process, wheel wear is inevitable, but diamond grinding wheels exhibit exceptionally slow wear rates. This is due to the extremely high wear resistance of diamond abrasive grains, which maintain stable grinding performance over extended periods of operation. This not only extends the service life of the grinding wheel and reduces replacement frequency, but also lowers production costs and enhances economic efficiency.

High precision is another significant advantage of diamond grinding wheels. Due to the minimal changes in size, shape, and morphology of diamond abrasive grains during the grinding process, diamond grinding wheels can achieve highly precise machining. In precision manufacturing fields such as aerospace and electronic chip production, where components require extremely high accuracy, diamond grinding wheels have become indispensable tools in these industries, thanks to their high-precision characteristics.

In addition, diamond grinding wheels also have low grinding force and good thermal conductivity. Low grinding force means that during the grinding process, the force exerted by the grinding wheel on the workpiece is relatively small, which can effectively reduce the deformation and damage of the workpiece and improve the machining quality; Good thermal conductivity is conducive to the rapid dissipation of heat, avoiding phenomena such as burning, cracking, or falling off of workpieces due to overheating, and further ensuring the surface processing quality of workpieces.

Widely used and indispensable

Diamond grinding wheels, with their excellent performance, play an indispensable role in many fields and have become a well deserved "star tool" in modern industrial manufacturing.

In the aerospace field, various components are made of high-strength and high hardness materials, which have almost stringent requirements for machining accuracy and surface quality. Take airplane engine blades as an example, they have complex shapes and special materials that traditional grinding tools are simply unable to handle. Diamond grinding wheels, on the other hand, can work stably in high temperature and high pressure environments due to their ultra-high hardness and wear resistance. They can finely grind and polish blades, ensuring that their dimensional accuracy and surface smoothness meet strict standards, providing strong support for manufacturing in the aerospace industry.

The mold manufacturing industry also relies on the assistance of diamond grinding wheels. The accuracy and surface quality of molds directly affect the quality and production efficiency of products. Diamond grinding wheels can efficiently grind hard materials such as mold steel, producing high-precision mold cavities and cores. Whether it is injection molds, stamping molds, or die-casting molds, diamond grinding wheels can leverage their advantages to help mold manufacturing companies improve production efficiency, reduce production costs, and enhance product competitiveness.

The semiconductor industry is one of the core industries of modern technology, and the requirements for processing accuracy have reached the nanometer level. In the semiconductor wafer processing, diamond grinding wheels are mainly used for cutting, grinding, and polishing processes. For example, in the wafer thinning process, the use of diamond grinding wheels can accurately control the thickness of the wafer within a very small error range, while reducing the surface damage layer and greatly improving the wafer yield. During the chip manufacturing process, diamond grinding wheels can also perform high-precision machining on the packaging substrate of the chip, ensuring the performance and reliability of the chip. It can be said that diamond grinding wheels are one of the key tools for achieving high-precision and high-efficiency production in the semiconductor industry.

The optical processing field has extremely high requirements for the surface quality and accuracy of materials. Diamond grinding wheels perform well in the processing of optical glass, crystals, and other materials. It can achieve ultra precision grinding and polishing of optical components, making the surface roughness of optical components reach the nanometer level, meeting the strict requirements of optical systems for component surface quality. For example, when manufacturing high-precision optical lenses, diamond grinding wheels can precisely grind the surface of the lens to achieve ideal optical performance, allowing us to see a clearer and better world.

The stone processing industry is the traditional application field of diamond grinding wheels. Whether it is cutting natural stones such as marble and granite, or grinding and polishing artificial stones, diamond grinding wheels have demonstrated extremely high efficiency and wear resistance. It can easily handle the hardness and brittleness of stone, achieving efficient and precise processing. Moreover, diamond grinding wheels can be customized according to the material and shape of the stone to meet the needs of different stone processing. In fields such as architectural decoration and tombstone carving, we can see the presence of diamond grinding wheels, which create various beautiful and durable stone products for us.

With the rapid development of technology and the continuous improvement of industrial manufacturing level, diamond grinding wheels, as a key grinding tool, have also ushered in new development opportunities and challenges. In the future, diamond grinding wheels will continue to move towards intelligent, green manufacturing, and extreme precision machining.