Henan Shili Diamond Products Co., Ltd., founded in 1992 and formerly known as Luohe Natural Diamond Products Factory, was established in 2003 with a registered capital of 12 million yuan and assets of 40 million yuan. It is a national high-tech enterprise that integrates research and development, production, and sales of diamond products.

Henan Strength:With diamond, we can handle porcelain work, and technological innovation welcomes a good start!

As a factory owner or production line manager in mechanical processing, are you constantly being overwhelmed by these challenges, leaving you with a headache every day?

"Three grinding machines are running non-stop, yet we still can't keep up with orders; the master is working overtime every day, yet the defective rate is shockingly high!" This is a common anxiety shared by many bosses in the mechanical processing industry. Do you think it's due to outdated equipment or insufficient manpower? In fact, the "invisible productivity assassin" hidden in the production process is the improper selection of grinding wheel dressing tools.

"Even with three grinding machines running non-stop, we still can't keep up with the orders. The master is working overtime every day, but the defective rate is shockingly high! "Using a single-point diamond pen to repair an arc raceway, we spend a long time adjusting the precision, but it's still not right.

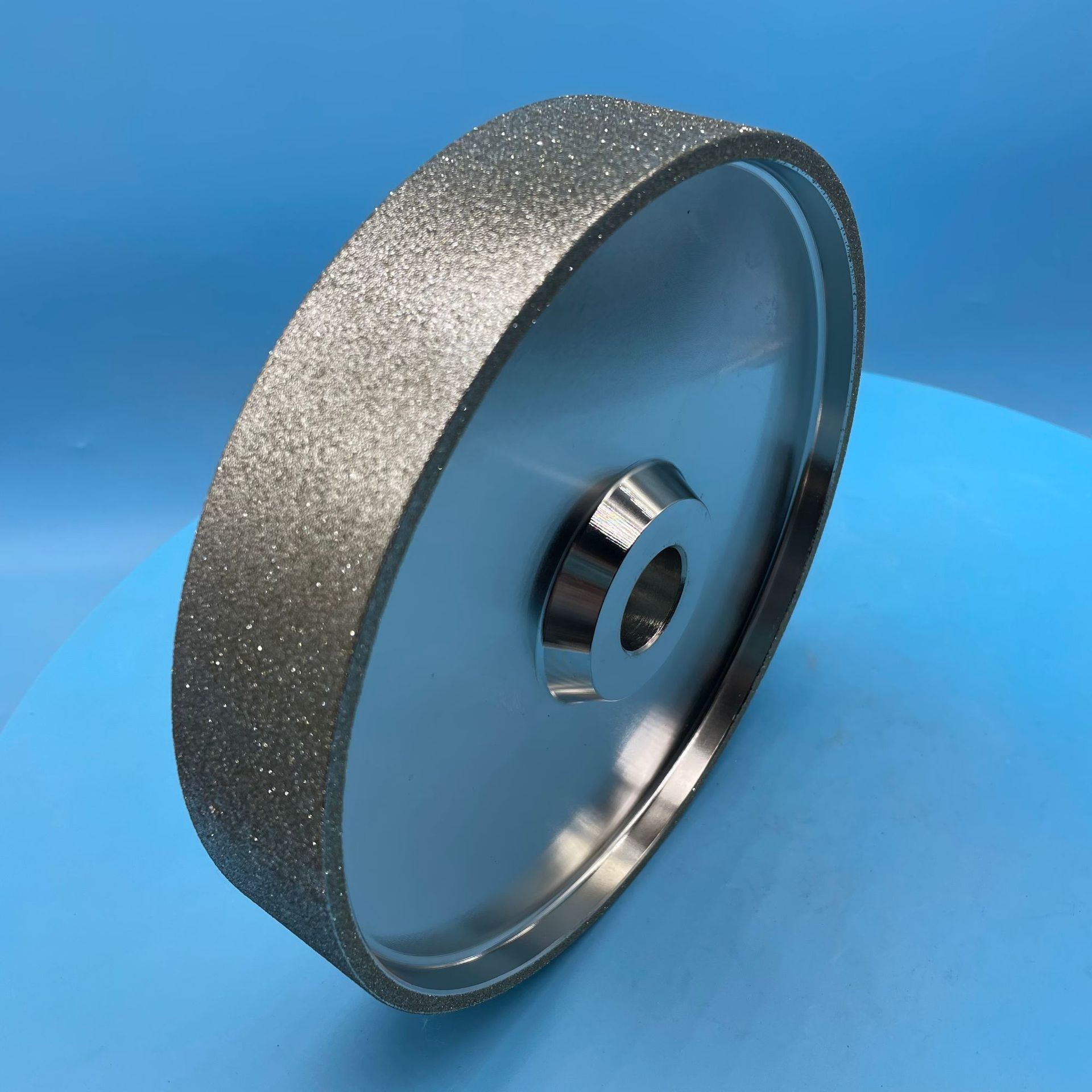

Diamond Grinding Wheel: The King Among Grinding Wheels Have you ever noticed that craftsmen use sophisticated tools when polishing hard materials? For instance, when working with jade, ordinary sandpaper is useless—specialized tools are essential to achieve a smooth and radiant finish. Today, we’ll explore the undisputed king of the grinding world—the diamond grinding wheel.

In the field of machining, hole processing has always been a critical factor affecting product quality and production efficiency. Are you still struggling with these issues? Repeated failures to meet precision standards, persistently high customer return rates; low machining efficiency, constant delays in order delivery; rapid tool wear, frequent replacements driving up costs... These pain points are severely constraining your production efficiency and even undermining your company's market competitiveness. Now, a product specifically designed to address these challenges—a diamond reamer—will deliver a completely new machining experience.

An Introduction to Diamond Grinding Wheels In the vast system of industrial manufacturing, there is a tool that may appear ordinary but plays a pivotal role—diamond grinding wheels. Simply put, diamond grinding wheels are circular fixed abrasive tools with a central through-hole, made from diamond abrasive grains as the raw material, combined with metal powder, resin powder, ceramics, or electroplated metal as binders. Despite their plain and unadorned exterior, their internal structure is highly sophisticated. Typically composed of a diamond abrasive layer, a transition layer, and a substrate, each layer performs its own function while working together to enable diamond grinding wheels to efficiently accomplish various grinding tasks.

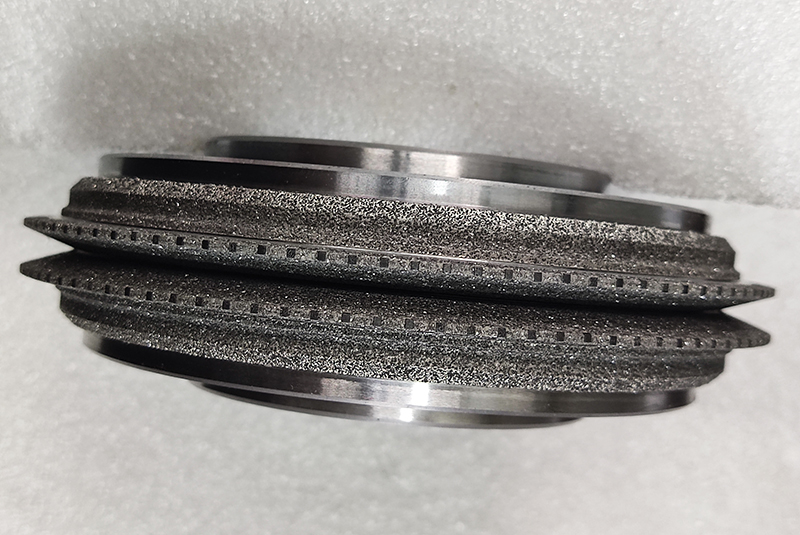

In the daily production of machining in factories, are you often troubled by these issues? Unstable machining precision leads to dimensional deviations exceeding standards in batches of workpieces, causing a sharp drop in product qualification rates and persistently high rework costs; inefficient grinding wheel dressing, where traditional dressing tools not only consume significant time but also require frequent replacements, severely slowing down production progress; over prolonged use, the wear costs of dressing tools continue to rise, greatly compressing a company's profit margins... If you are facing these challenges, consider learning about the "game-changer" that can completely transform the current situation—the diamond dressing wheel.

In factory processing and production, are you still struggling with these issues? Precision hole machining consistently fails to meet standards, leading to repeated rework that not only wastes raw materials but also severely delays production progress; ordinary reamers wear out too quickly, frequent tool replacement increases procurement costs and causes frequent production line interruptions; when faced with workpiece materials of high hardness, commonly used tools are inadequate, resulting in uneven machining quality that affects the overall product quality... Are these pain points severely constraining your factory's production efficiency and economic benefits?